October 15, 2025

The Sparta Bronco Round Container is a testament to durability and smart design. It’s not just a basic c...

October 14, 2025

Introducing an industrial disposable glove designed to wick away moisture, keeping your hands cool and d...

October 10, 2025

A versatile solution for cleaning, sanitizing, and disinfecting—all in one product! Alpet D2 Flex has be...

September 25, 2025

An innovative lobby dustpan that transforms commercial cleaning. This is not just a basic dustpan; it ha...

September 10, 2025

Food safety is an ongoing commitment. It demands continuous vigilance, collaboration, and access to a we...

August 8, 2025

Innovative sensors can provide solutions and drive progress as evident in the value of in-line turbidity...

July 15, 2025

Food safety is a primary concern for any manufacturer, driven by existing and new threats that call for ...

July 1, 2025

PPE vending machines offer numerous advantages over traditional PPE distribution methods, especially in ...

June 30, 2025

In the competitive food manufacturing landscape, minimizing waste is no longer just an ethical choice – ...

June 27, 2025

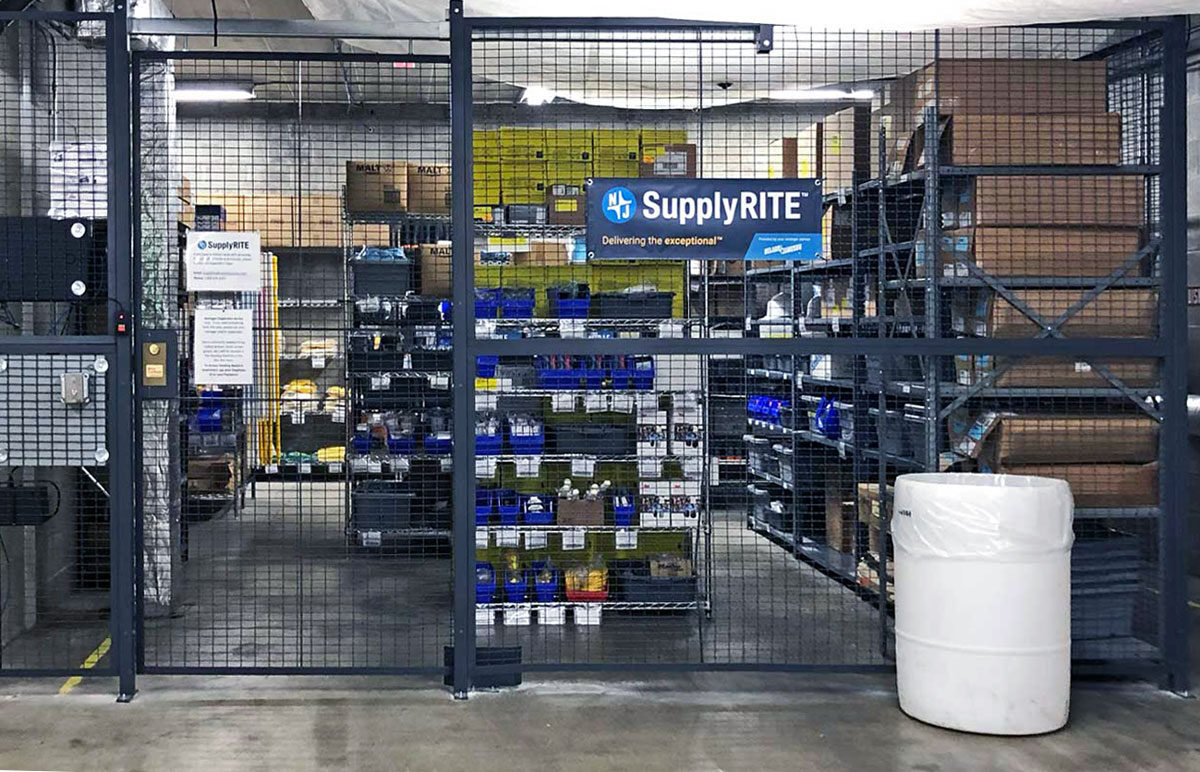

Avoiding stock-outs of crucial supplies is essential for uninterrupted operations and maintaining safety...

June 26, 2025

In the food manufacturing industry, efficient inventory management is crucial for maintaining smooth ope...

June 26, 2025

Effective inventory management is essential in food manufacturing facilities – particularly for plant wo...