May is Food Allergy Month and this week is Allergen Awareness Week. For the approximate 15 million Americans that have some sort of food allergy, it can be an exhausting task to grocery shop. Each aisle might feel a bit like a minefield. Carefully negotiating the vast array of products to ensure they can find the right foods for themselves and their families may bring stress and trepidation.

May is Food Allergy Month and this week is Allergen Awareness Week. For the approximate 15 million Americans that have some sort of food allergy, it can be an exhausting task to grocery shop. Each aisle might feel a bit like a minefield. Carefully negotiating the vast array of products to ensure they can find the right foods for themselves and their families may bring stress and trepidation.

On the production side, it can also be daunting for food producers to think about successfully handling allergens in their production process, including the possibility of cross-contamination. Daunting as it may be, lives depend on food processors getting a handle on food allergen concerns and ensuring their products are labeled correctly. Consumers depend on producers to help them negotiate the minefield of allergens and deliver them to the checkout with a sense of security and peace that they have purchased the right food for themselves and their loved ones.

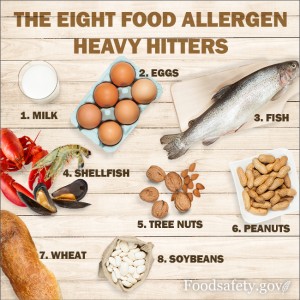

A good deal of emphasis is placed on the so-called “Big 8” allergens: milk, egg, fish, shellfish, tree nuts, peanuts, wheat and soy. Nelson-Jameson stocks a variety of allergen testing supplies that are important parts to an operation’s needs. Recently, Neogen just released the new, long awaited, Reveal Multi-Tree Nut Allergen Test Kit that tests for cashews, pecans, almonds, pistachio, hazelnuts and walnuts.

At Nelson-Jameson we are always here to help give you peace of mind when dealing with the allergen issues that face us, so that your customers can feel some peace of mind, too.

February 11, 2026

There is a critical link between worker safety and food safety, and nowhere is this more apparent than w...

February 3, 2026

Ensuring the safety and quality of dairy products requires a robust framework combining rigorous testing...

January 12, 2026

Gloves can force a choice between comfort and protection. But compliance, efficiency in usage, and worke...

Recognize and address possible hygiene and sanitation challenges based on the cleaning and material handling equipment available in your facility.

Through a discovery call, virtual, or on-site assessment, Vikan SQF Practitioner certified specialists will assist in confirming that your system and cleaning tool inventory aligns with your risk management objectives while pinpointing any missing tools and enhancing maintenance and usage practices. Evaluate whether your existing tools are utilized in the most effective manner, or determine if a more suitable tool exists for the task at hand. Ensure that your tools comply with all relevant standards and regulatory requirements. Site evaluations encompass a summary survey, an overview of the location, a color-coded factory layout plan, product suggestions, a recommended order form, and a proposal for a follow-up survey.

Food Safety, Sanitation, Cleaning Tools, Color Coding

This is a comprehensive program for the food processing industry. Nelson-Jameson brings together the most extensive collection of color-coded products for material handling, product handling, janitorial, safety, apparel, QA/QC, and metal-detectable applications. With the right pieces, a color-coding system is a powerful tool in preventing cross-contamination of allergens and food-borne illnesses that can lead to sickness or expensive product recalls.

Food Safety, Sanitation, Cleaning Tools, Color Coding

Food Safety

Get Petrifilm Certified through our complimentary immersive workshop for managers, personnel, and teams. The workshop offers practical knowledge through hands-on training and networking with industry professionals and experts. Attendees gain an in-depth understanding of Petrifilm technology and valuable insights into effective environmental monitoring practices. Participants leave with a certification and a wealth of resources that can significantly contribute to elevating their plant's quality control standards.

Food Safety, Sanitation, Laboratory