On a global scale, the United States food supply is one of the safest. However, it’s still important to maintain a focus on protecting consumers from preventable foodborne diseases. One simple step can be taken to prevent cross-contamination of allergens that can lead to sickness or extremely costly recalls: a color-coding system for tools.

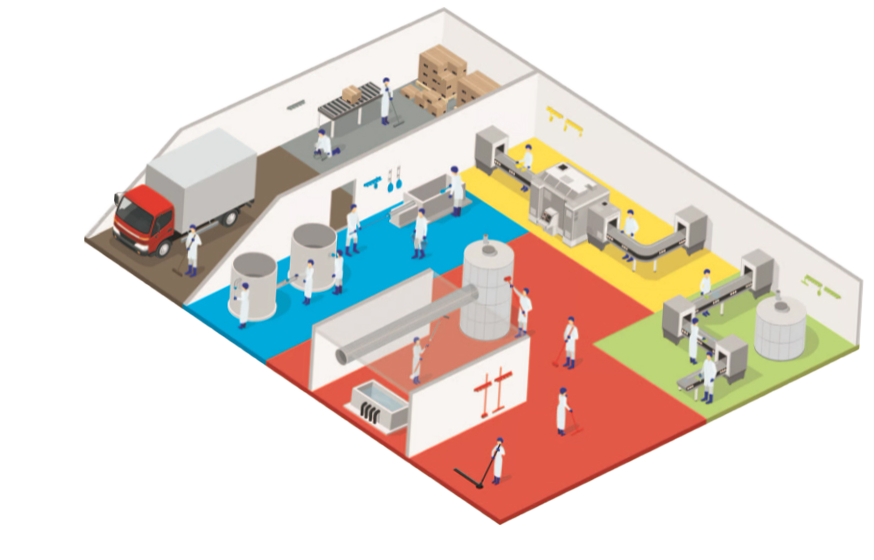

Color-coding tools, clothing, supplies, and more (see our color-coding products here) in a food processing facility allows for easy and quick identification and communication of information that’s essential for food safety and protects employees and consumers. Designating critical control areas and zones helps your sanitation program by ensuring that the tools stay in the areas in which they are meant to be used, doing jobs they are meant to do.

Color-coding programs also help avoid bacterial and allergen cross-contamination within a facility or from one application to another, allowing you to maintain a safe food processing facility.

Read on for our simple steps for developing and maintaining a color-coding program in your facility for a safer environment for workers and consumers. Just getting started and want to know "What is color coding?" Click here for our complete guide!

An allergen is a substance that causes an allergic reaction, which occurs when the immune system overreacts to a normally harmless substance known as an allergen.

The United States FDA lists nine major food allergens:

The European Union has even more allergens, with 14 currently listed

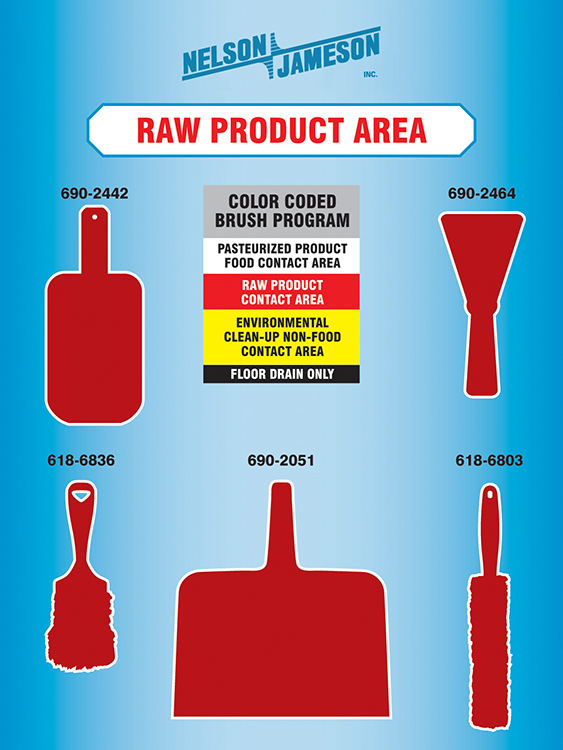

Segregation of allergen production areas by color provides an easy visual check that only tools and utensils color-coding to use in that specific area are used. For example, the use of lime-colored equipment should only be used in the lime-colored "allergen" production area. The more unusual colors like orange, pink, purple, and lime are often chosen for use with allergens.

It is critical to take your time while developing your facility's color-coding program. Consult with employees at all levels in your facility and consider doing a trial run of the tools. Try to keep the plan simple and consistent and communicate the plan effectively and often to reinforce the importance and how such measures can enhance food safety and improve organizational efficiency. Educating and training employees is a critical step in implementing your color-coding program.

By providing clear training and concepts of your plan, employees will better understand why preventative control is important in preventing cross-contamination of allergens.

Shadowboards can be very helpful in keeping tools organized in their designated areas.

Nelson-Jameson can help your facility by customizing shadow boards to any design and style you require—use any color, logos, messages, symbols, or full-color images of your choice.

Color-coding facilities is crucial in protecting against costly and dangerous cross-contamination of allergens. Be sure that your facility is protecting itself and consumers by utilizing the color-coding system. Learn more about your options below:

February 11, 2026

There is a critical link between worker safety and food safety, and nowhere is this more apparent than w...

February 3, 2026

Ensuring the safety and quality of dairy products requires a robust framework combining rigorous testing...

January 12, 2026

Gloves can force a choice between comfort and protection. But compliance, efficiency in usage, and worke...

Recognize and address possible hygiene and sanitation challenges based on the cleaning and material handling equipment available in your facility.

Through a discovery call, virtual, or on-site assessment, Vikan SQF Practitioner certified specialists will assist in confirming that your system and cleaning tool inventory aligns with your risk management objectives while pinpointing any missing tools and enhancing maintenance and usage practices. Evaluate whether your existing tools are utilized in the most effective manner, or determine if a more suitable tool exists for the task at hand. Ensure that your tools comply with all relevant standards and regulatory requirements. Site evaluations encompass a summary survey, an overview of the location, a color-coded factory layout plan, product suggestions, a recommended order form, and a proposal for a follow-up survey.

Food Safety, Sanitation, Cleaning Tools, Color Coding

This is a comprehensive program for the food processing industry. Nelson-Jameson brings together the most extensive collection of color-coded products for material handling, product handling, janitorial, safety, apparel, QA/QC, and metal-detectable applications. With the right pieces, a color-coding system is a powerful tool in preventing cross-contamination of allergens and food-borne illnesses that can lead to sickness or expensive product recalls.

Food Safety, Sanitation, Cleaning Tools, Color Coding

With existing and emerging threats, food safety has never been more important to food manufacturers in protecting their consumers and their organization.

Color Coding

Laboratory, Color Coding, Food Safety