Improve food safety through color-coding

Nelson-Jameson brings together the most extensive collection of color-coded products for material handling, product handling, janitorial, safety, apparel, QA/QC, and metal-detectable applications.

With the right pieces, a color-coding system is a powerful tool in preventing cross-contamination of allergens and food-borne illnesses that can lead to sickness or expensive product recalls.

Color-coding tools, clothing, and supplies enable fast and simple identification and communication of information within food manufacturing facilities. It’s the best way to visibly designate critical control areas and zones that help your sanitation program by ensuring that tools stay in the places where they are meant to be utilized.

Color-coding programs also help avoid bacterial and allergen cross-contamination within a facility or from one application to another, allowing you to maintain a safe food manufacturing facility. Want to start or complete your color-coding program? We’ve put a buyer’s guide with everything a food manufacturing plant needs.

No color-coding program is complete without color-coded brushes. Ensure every aspect of a food processing facility is clean and organized to prevent any cross-contamination from sharing brushes through a facility.

Color-coded brooms

Brooms are an essential tool in every part of a food manufacturing facility. It’s crucial that brooms are durable for consistent usage and color-coded to ensure that they’re used only in designated areas to prevent cross-contamination.

Color-coded mops and buckets

Like brooms, quality, and identifiable mop heads and buckets are crucial tools in every part of a food manufacturing facility. Mops must be durable for consistent usage and color-coded to ensure they’re used in their designated areas to stop cross-contamination.

Color-coded squeegees

Quality squeegees are a must for any food safety plan. Prevent cross-contamination from liquids in any food manufacturing facility with color-coded squeegees that are easy to clean and easy to identify.

Color-coded scoops

Scoops are ideal for use in food production areas for moving food ingredients, liquids, and more. But in order to prevent-cross contamination, a color-coding system is a must for scoop organization in any food manufacturing facility.

Color-coded material handling equipment

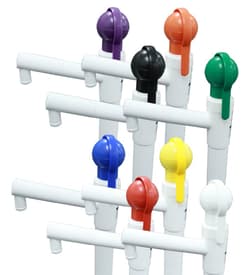

A proper color-coding plan spans the entire facility. Buckets, hair nets, pens, boot covers, shoe laces, scrapers, bibs, and much more can be color-coded to complete this important piece of a food safety plan for any food processing facility.

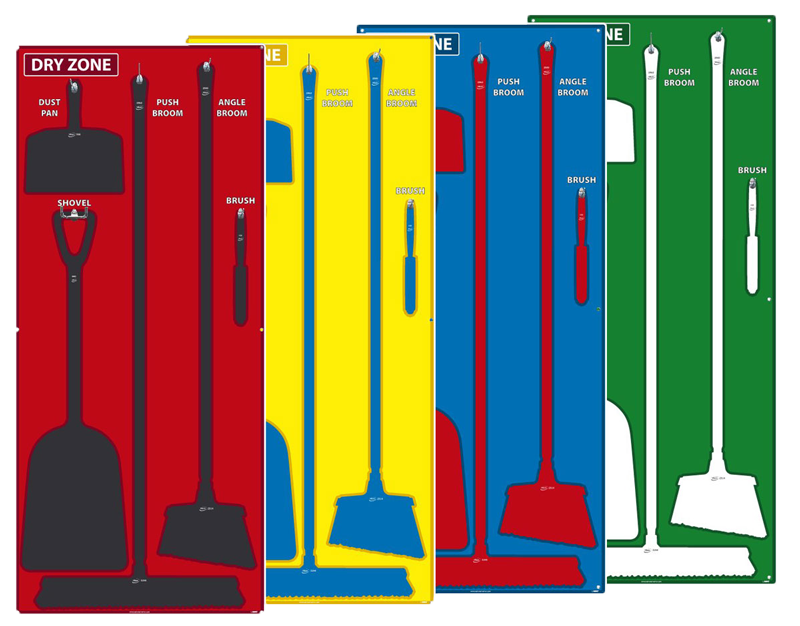

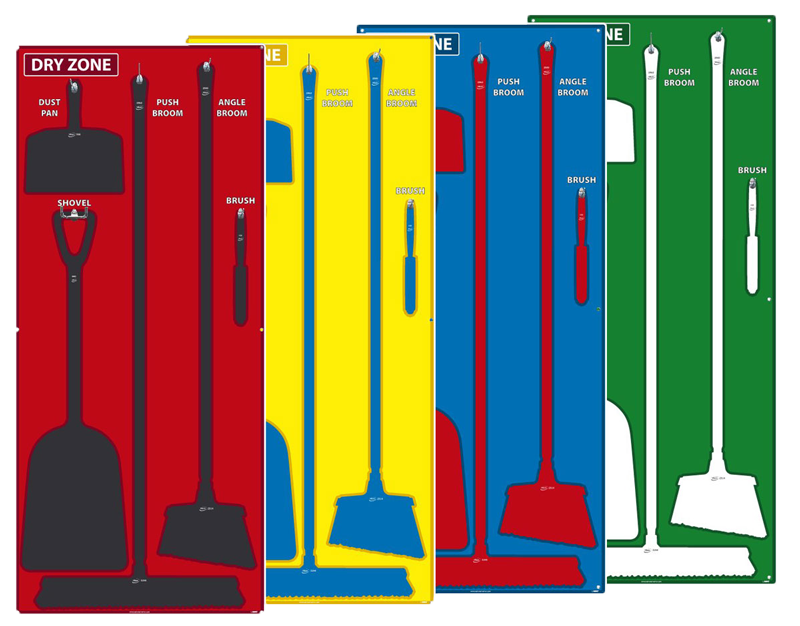

Custom Shadow Boards

Upgrade your SQF and 5S Lean Manufacturing initiatives and help prevent cross-contamination in your facilities by organizing your color-coded tools with a custom shadow board from Nelson-Jameson.

Color-coded PPE

Personal protective equipment (PPE) should keep workers safe. But it’s also important to ensure it’s color-coded to prevent cross-contamination and keep consumers safe along with those in the facility.

Color-coded facility identification

Facility identification refers to signs and tags that call attention to spaces or equipment. These important tools for food manufacturing can also be color-coded to ensure equipment is locked up safe as well as safe from contamination.

Facility Safety Identification Assessment

AccuformNMC offers professional safety services designed to enhance your workplace safety program and ensure compliance with OSHA, ANSI, EPA, MUTCD, and NFPA standards. A specialist will conduct an on-site evaluation and provide a comprehensive report after the visit, including an action plan focused on improving safety in your facility.