Have you ever missed one or two of your normal tooth-brushing sessions, and found your tongue traversing over a disconcertingly slimy layer coating your chompers? Well, welcome to the disturbing and quite fascinating world of biofilms. These hearty amalgams of microbiological activity provide both protection for microorganisms, as well as headaches for not only those avoiding plaque build-up, but most importantly for this blog, the food industry (allowing harborage and protection for bacteria and fungi).

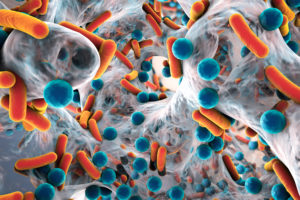

Biofilms can form on a variety of surfaces in food processing environments, including stainless steel. A supercell of harborage, “Biofilms are complex microbial ecosystems formed by one or more species immersed in an extracellular matrix of different compositions depending on the type of food manufacturing environment and the colonizing species” (Geaile, et al). The “matrix” formed creates a powerful source of protection and fuel for the continued life and shear tenacity of these “eek-osystems” to affect, disrupt, and harm products.

Though biofilms are capable of creating a lot of hassle when it comes to cleaning, spoilage concerns, etc., Gaile, et al, in “Biofilms in the Food Industry: Health Aspects and Control Methods” note: “Of particular importance to the food industry is that some biofilm-forming species in food factory environments are human pathogens.” With biofilms aiding and abetting pathogens, the cost of not waging an effective sanitation onslaught, may create food safety issues of serious proportions. This is even further complicated by the fact that, “Mixed biofilms show higher resistance to disinfectants such as quaternary ammonium compounds and other biocides” (Gealie, et al.). This means traditional cleaning protocols may not be enough to counter the threat biofilms pose to public health.

Here at Nelson-Jameson, we continue to work with our supplier-partners to take on the threat of biofilms in the food industry. Our hope is that through a multi-pronged approach, we can help address this serious concern for our customers. Here are just a few of the ways we are taking on the challenges of biofilms currently:

- Providing effective and efficient cleaning solutions, like hygienic brushes and squeegees from Remco and Carlisle, to cleaning chemical options from Hydrite, Kersia, and Best Sanitizers.

- Formulating and offering the best enzymatic cleaning solutions with Realzyme.

- Offering the best in testing solutions, including 3M Petrifilm and ATP testing equipment, as well as offering sampling collection/sample integrity products from Whirl-Pak and QualiTru.

Though continuing to be a tough challenge for the food industry, biofilms will squarely be in the crosshairs of our team and our supplier partners. Together, across the industry, we can seek out effective solutions, and build tailored programs to take on the challenge and the tenacity of biofilms in the production environment. For an excellent resource on biofilms please be sure to consult the Gealie et al. article referenced above, here: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5949339/.