Protection from hazardous agricultural chemicals during indoor cultivation

Pesticide safety for agricultural workers must be seriously considered because chemicals from indoor farming can pose health and safety risks. Taking appropriate precautions and using proper personal protective equipment for indoor growing can reduce the risk of dangerous exposure.

A detailed understanding of the substances being used and their level of risk is crucial in determining the appropriate personal protective equipment for cannabis farming, commercial hydroponics, and other large-scale indoor agriculture setups.

Cultivation & extraction applications

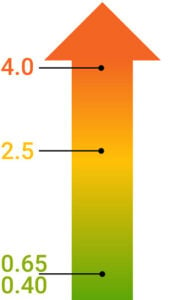

Confirm which disposable glove is safe for your application by using the Acceptable Quality Level (AQL) measurement system. Exam grade gloves with an AQL of 2.5 or less are recommended for use in the cultivation process to reduce the risk of tears.

Chemical handling

A protective barrier against hazardous chemicals—reducing direct exposure.

What is an Acceptable Quality Level (AQL)?

A standard testing process to evaluate the integrity of a disposable glove. The AQL measurement determines the highest number of defects (holes) accepted in a randomly selected batch of gloves. The lower the AQL, the better the quality of the glove and the less likely there will be defects.

AQL 4.0 | Suitable for industrial applications |

AQL 2.5 | Minimum standard for medical applications |

AQL 0.65 | Better AQL than standard exam-grade gloves |

AQL 0.4 | Highest known standard for barrier quality and consistency |

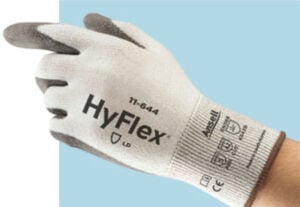

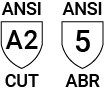

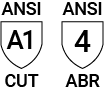

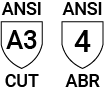

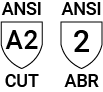

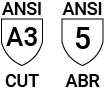

Cut-resistant gloves

Ansell gloves are assigned an ANSI cut resistance level (A1 to A9) using the ASTM F2992-15 testing method. Gloves are rated by the weight (in grams) needed to cut through the material—the higher the weight, the higher the cut level and the better protection for high-risk applications.

Applications with a low cut risk:

A1 through A3

Applications with a high risk of cuts & lacerations:

A4 through A9

Cut-resistant levels:

| ANSI Level | Weight in grams needed to cut through glove material | Typical Tasks |

| A1 | ≥200g | General purpose, warehousing, small parts assembly |

| A2 | ≥500g | General purpose, plastics injection and moulding, pulp and paper |

| A3 | ≥1,000g | Raw material handling, general manufacturing, construction |

| A4 | ≥1,500g | HVAC, aerospace, food prep |

| A5 | ≥2,200g | Glass or metal sheet handling, automotive assembly, HVAC |

| A6 | ≥3,000g | Metal fabrication, glass manufacturing, changing blades |

| A7 | ≥4,000g | Meat prep/processing, glass manufacturing, metal stamping |

| A8 | ≥5,000g | Metal stamping, recycling, heavy assembly |

| A9 | ≥6,000g | Sharp metal stamping, recycle sorting, metal fabrication |

Glove material comparisons

| Glove Material | Comfort | Performance | Protection | Comment |

|---|---|---|---|---|

| Natural Rubber Latex |  |  |  | • Highest comfort with elasticity & dexterity • Great wet and dry grip • Allergenic: Type I and Type IV |

| Nitrile |  |  |  | • Strong and durable material • Excellent puncture and abrasion resistance • Good chemical splash resistance |

| Neoprene |  |  |  | • Broad chemical splash resistance • Maintain flexibility across wide range of temperatures • Consistent performance even in wet environments |

| Polyisoprene |  |  |  | • As comfortable as natural rubber latex • Second skin fit and feel • Reduces the risk of Type I and Type IV allergies |

| Vinyl |  |  |  | • Most economical • Provides lowest level of protection and performance |

Low Low |  Moderate Moderate |  High High |  Very High Very High |

- Color-coded gloves for different applications can help prevent cross-contamination and allow for easy identification.

- A thicker mil glove does not equate to chemical protection—the composition material does.

- Using ergonomically designed gloves can help support musculoskeletal health and reduce hand fatigue.

AnsellGUARDIAN® PPE Assessments

Personalized risk management solutions to optimize PPE dispensing and business performance. Improve worker safety, increase productivity, and lower overall costs.

Looking for More Ansell Safety Products?

Download our Ansell Safety Products flyer or request a free copy today!

0.65 AQL

0.65 AQL

1.5 AQL

1.5 AQL