SealRite™ Permanent Crimp: Fluoropolymer Hoses

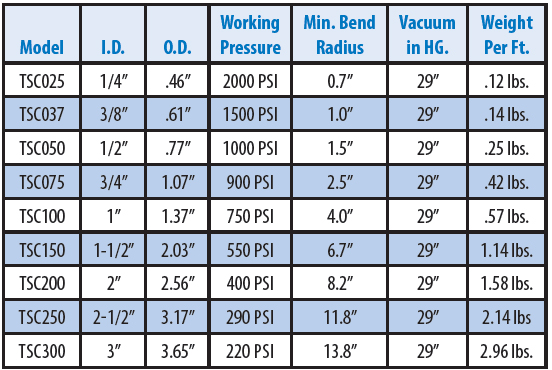

TSC Silicone Covered Smooth Bore

This silicone covered, PTFE lined hose with exterior convolutions and a smooth, undulating bore provides extreme flexibility. Exceptional for High Purity use in pharmaceutical, biotech and food industries. This hose will not impart taste or odor to products being transferred and provides cleaning ease both inside and out. TSC is excellent for use in hot oil or low velocity steam transfer applications.

TUBE: PTFE unpigmented, USP Class VI & FDA, (anti-static opt. avail.)

REINFORCEMENT: Stainless Steel Braid

TEMP. RANGE: -80° to 400°F 3-A

COVER: White, Platinum Silicone Rubber

LISTED: 3/4" I.D. and over

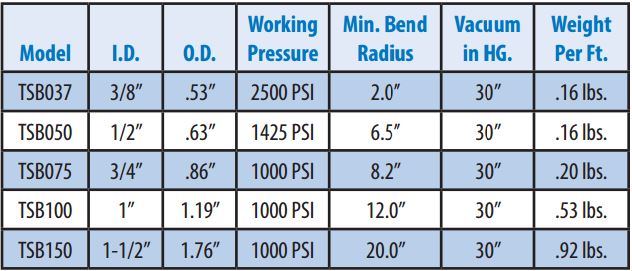

TSB Stainless Steel Braided Smooth Bore

Excellent for fixed applications where minimal abuse, handling or flexing exist. Available for "Flaired Through" applications. Hose cover options available.

TUBE: PTFE unpigmented, USP Class VI & FDA Criteria

REINFORCEMENT: 1" & 1-1/2" double braided

TEMP. RANGE: -20 to 425°F

COVER: Stainless Steel Braid

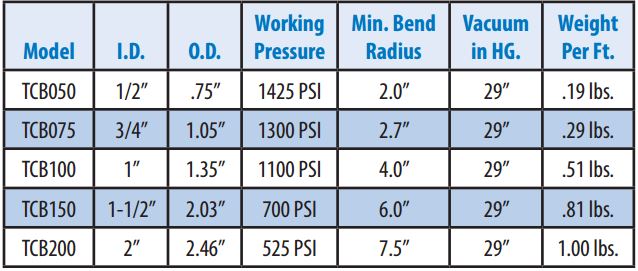

TCB Stainless Steel Convoluted

Crush resistant hose that is easy to flex and has a tighter bend radis than smooth bore. Openpitched, seamless, helical convolutions provide for easy cleaning and transport of pharmaceuticals, chemicals, food and beverages. Hose cover options available.

TUBE: PTFE unpigmented, USP Class VI & FDA Criteria

TEMP. RANGE: -20 to 425°F

COVER: 316 Stainless Steel Braid

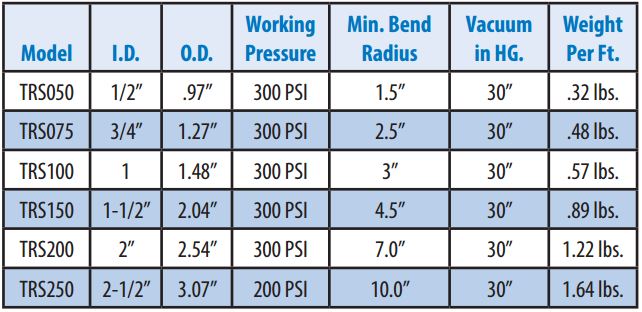

TRS EPDM Covered Smooth Bore FEP

A steel wire is helically wound through the carcass which provides crush, kink and vacuum resistance. Ideal where external abrasion resistance is required.

COLOR: Green

TUBE: FEP white, USP Class VI & FDA Criteria

REINFORCEMENT: Steel wire, helically wound

TEMP. RANGE: -20 to 300°F

COVER: Green EPDM w/ white stripe

| 1) Select code for specific hose |

| - Rubber Hoses |

| - PVC Hoses |

| - Silicone Hoses |

| - Fluoropolymer Hoses |

| 2) Specify hose ID |

| 3) Coupler Style (SL = radial crimp) |

| 4 & 5) Specify size and connection of each end fitting |

| 6) Hose sleeve material (S = stainless steel) |

| 7) Specify overall assembly length in inches |

| 8) Call Customer Service at 800-826-8302 |