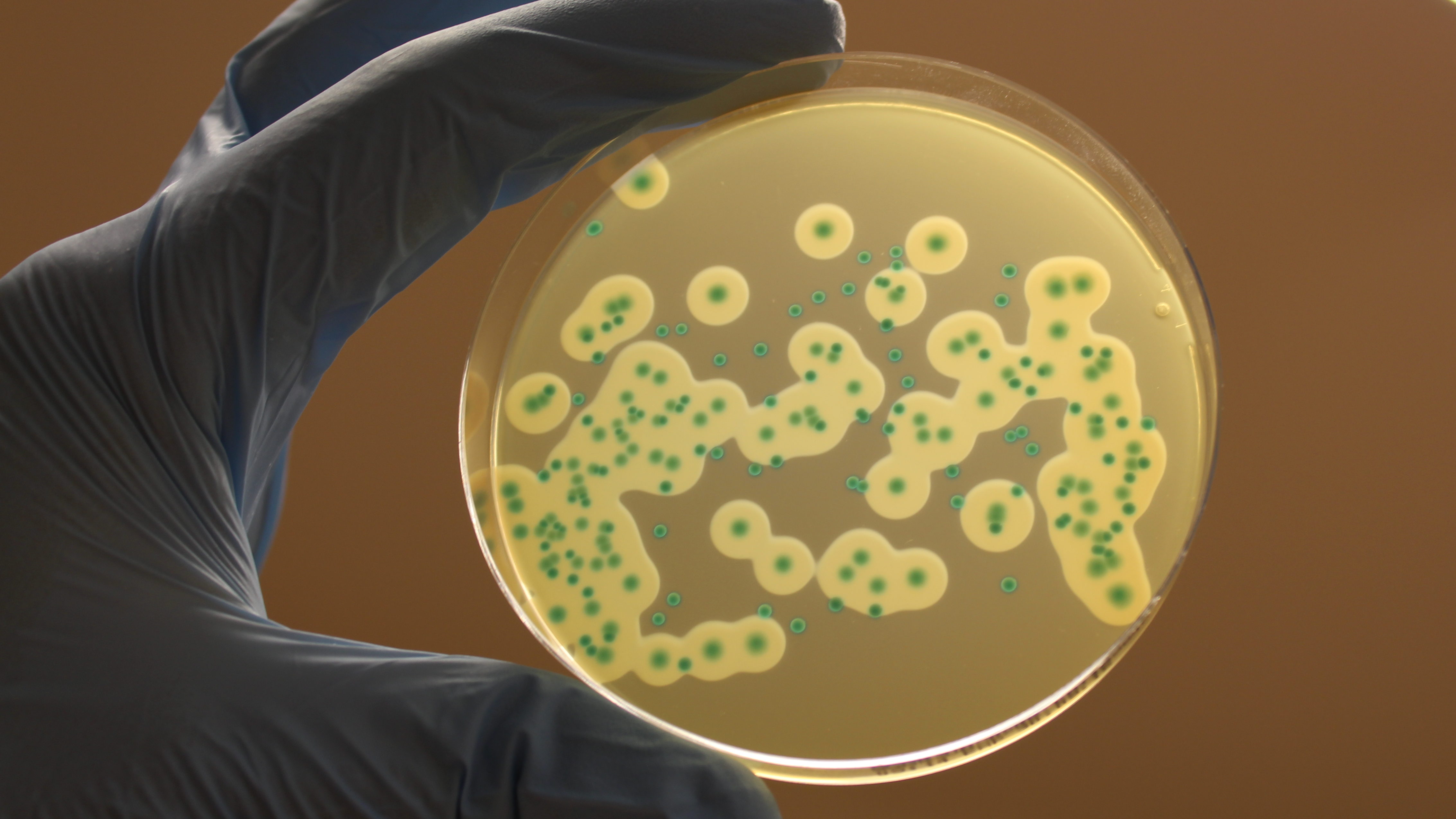

Listeria, a bacterium responsible for listeriosis, presents a significant concern due to its relatively high mortality rate, leading to approximately 260 deaths annually in the United States, according to the Centers for Disease Control. Unlike some isolated super-bug, Listeria monocytogenes is commonly found in soil and water, and animals can carry the bacterium without showing signs of illness, potentially contaminating foods of animal origin. Moreover, when Listeria enters a food processing factory, it can persist for years, posing a threat to food products. Consumers and food processors alike are keenly aware of the need for effective prevention measures.

While consumers can refer to resources like the CDC and FDA for prevention information, food processors must focus on stringent practices and standards. Areas such as cleaning and sampling, ensuring proper temperatures during processing, and implementing strategies to prevent cross-contamination play a crucial role in minimizing the risk of Listeria contamination. Nelson-Jameson offers a comprehensive range of products, including sanitizing solutions, thermometers, and color-coded tools, to aid in Listeria prevention efforts for both consumers and food processors. Explore our extensive collection to enhance your sanitation program and ensure food safety.

The Centers for Disease Control estimates "approximately 1600 illnesses and 260 deaths due to listeriosis [infection caused by listeria] occur annually in the United States." Even though responsible for fewer illnesses than other pathogens that are out there, listeria's relatively high mortality rate (especially for certain segments of the population) naturally resonates with both consumers and food producers as a focus for concern.

Consumers may be surprised to find out that, opposed to being some isolated super-bug, " Listeria monocytogenes is commonly found in soil and water. Animals can carry the bacterium without appearing ill and can contaminate foods of animal origin, such as meats and dairy products." Beyond that, food processors, understanding the threat that listeria presents, are especially concerned with the fact that: "When Listeria bacteria get into a food processing factory, they can live there for years, sometimes contaminating food products"(CDC).

Consumers can check out information on prevention from the following sources:

Food processors, in addition to reviewing practices/standards, and reviewing local, state, and federal resources to address the issue, can also focus on some of the following areas to help minimize risk:

A complete color-coded system helps your sanitation program by assuring that plant tools stay in the areas in which they are meant to be used, doing jobs they are meant to do. This helps stop bacterial migration between areas of the plant, and even from one application to another.

Nelson-Jameson brings together the most extensive collection of color-coded products for materials handling, product handling, janitorial, safety, apparel, QA/QC, and metal-detectable applications. View our complete collection here and learn about a color coding assessment here!

For more information contact our Customer Service Department 800-826-8302.

Sources: Centers for Disease Control and Prevention (CDC); U.S. Food and Drug Administration (FDA).

Hailey is a Product Manager - Laboratory Products at Nelson-Jameson.

February 11, 2026

There is a critical link between worker safety and food safety, and nowhere is this more apparent than w...

February 3, 2026

Ensuring the safety and quality of dairy products requires a robust framework combining rigorous testing...

January 12, 2026

Gloves can force a choice between comfort and protection. But compliance, efficiency in usage, and worke...