Custom shadow boards offer numerous advantages, contributing to the efficient organization of tools and the enhancement of workplace safety. Aligned with the principles of the 5S methodology—Sort, Set to Order, Shine, Standardize, and Sustain—custom shadow boards play a crucial role in fulfilling these requirements. The choice of material is a pivotal decision, and there are three options available to cater to different purposes: General Purpose Composite, Industrial Grade Aluminum, and Pro Series Acrylic. Each material has distinct features and temperature ranges suitable for various environments. To create a custom shadow board, a step-by-step process is outlined. It begins with selecting the board material, followed by identifying the tools to be shadowed, choosing the title and background color, specifying the board size, and considering additional information like color-coding charts, company name, logo, or images. By following these steps, businesses can tailor their shadow boards to optimize organization and efficiency while maintaining a visually appealing and informative workspace.

Custom shadow boards help fulfill the requirements of 5S.

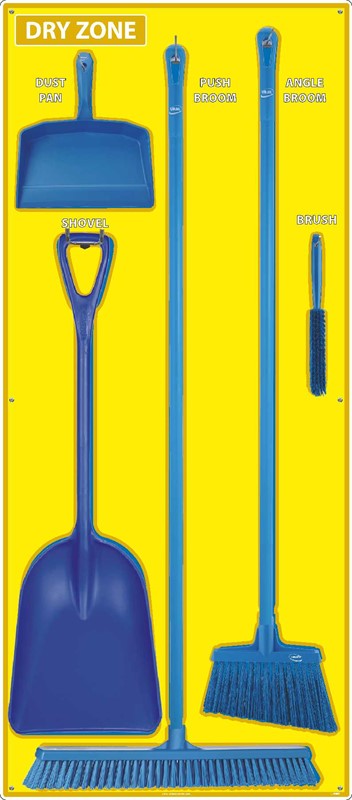

Sort: Separate tools that are needed to get the job done and remove everything else.

Set to Order: Place all relevant tools within reach of operatives and reduce the need to be away from the workstation.

Shine: Maintain safety and order in the workplace by keeping the tools clean and helping to reduce defects.

Standardize: Create practices that will ensure maintenance of the steps you have already taken by introducing Shadow Boards.

Sustain: Stay consistent and constantly review standards.

There are three options available depending on the purpose

of your shadow board.

Choose from General Purpose Composite, Industrial Grade Aluminum, or Pro Series Acrylic.

List manufacturer, part numbers and descriptions, or take a clear, straight-on picture of each tool next to a ruler.

Choose the title and background color of the board, and the title and shadow color of the tools.

If size is not an issue, board can be created to fit the tools with minimal blank space.

Consider adding your color-coding chart, company name, logo, or other images by supplying a vector file (.EPS or .AI)*.

*A .JPEG can be used if it doesn't need enlargement.

Information provided by AccuformNMC.

Contact our Product Specialists for additional information:

sales@nelsonjameson.com or 800.826.8302

February 11, 2026

There is a critical link between worker safety and food safety, and nowhere is this more apparent than w...

February 3, 2026

Ensuring the safety and quality of dairy products requires a robust framework combining rigorous testing...

January 12, 2026

Gloves can force a choice between comfort and protection. But compliance, efficiency in usage, and worke...