Welcome to our exploration of wet mops for cleaning and maintenance, brought to you by Nelson-Jameson. This comprehensive guide sheds light on different yarn materials, such as Cotton, known for its absorption and cost-effectiveness, and Rayon, prized for quick absorption and resistance to mildew. Discover the advantages of Cotton/Synthetic Blend, a harmonious fusion of performance and durability. The guide also delves into the distinction between Cut-End and Looped-End Mops, offering valuable insights into their characteristics, cost considerations, and longevity. Whether you're looking to understand the nuances of yarn materials or seeking guidance on mop types, our mop buying guide equips you with essential knowledge. Additionally, explore care and maintenance tips for maximizing the lifespan of your mop heads, and learn about the benefits of Color-Coded Mops in preventing cross-contamination. Enhance your understanding of yarn varieties and elevate your cleaning practices with Nelson-Jameson's expertise.

Cotton: Good absorption and retention with limited shrinkage and a low initial cost. Requires a "break-in" period to remove natural oil and gain full absorbency of mop. Slow drying yarn promotes mildew and deterioration. Lints.

Rayon: Absorbs quickly with easy release, however has low water retention making it less effective for general cleaning. Dries fast and is mildew resistant. Cleaner yarn with less linting. Used primarily in special applications such as floor finishing.

Cotton/Synthetic Blend: Combines high performance with long product life. Cotton fibers provide high water absorption and retention for effective floor drying. Synthetic fibers provide maximum water pick up and strength for increased product life. No "break-in" required.

Most popular, with lower purchase prices and perceived to be more economical. However, because cut-end mops cannot be laundered they are often thrown away before their lifespan is complete, making their ultimate cost higher. They can fray and unravel with use and have a tendency to leave behind loose strands and lint.

Offers a more superior performance and lasts longer than cut-end style mops. Prevents fraying and unraveling, resulting in reduced labor costs and lower replacement cost. Can be laundered. With proper laundering, mop will last 8 to 10 months longer than cut-end mops.

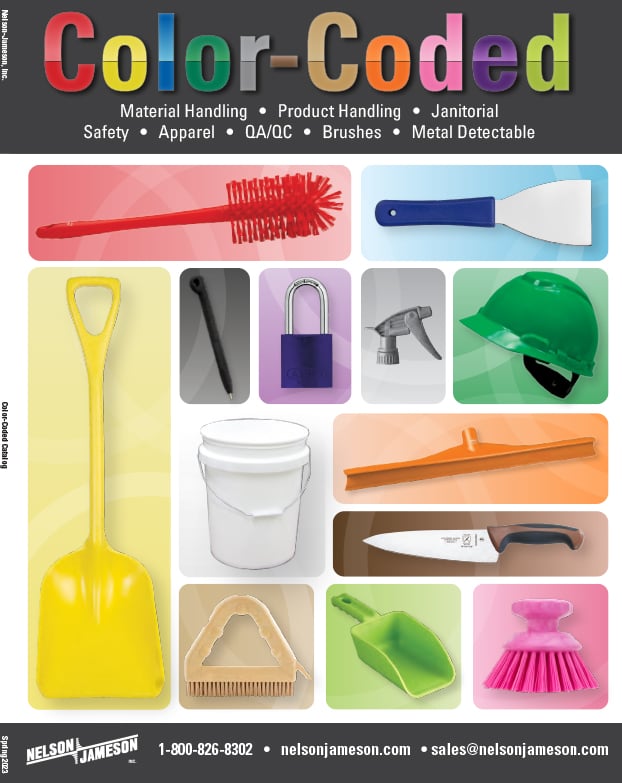

Many of our wet mops are available in color-coded options to help prevent cross-contamination in your plant. To learn more, download a copy of our Color-Coded Catalog today.

January 12, 2026

Gloves can force a choice between comfort and protection. But compliance, efficiency in usage, and worke...

January 2, 2026

From regulatory updates to evolving needs for operational efficiency, food processors spent 2025 adaptin...

December 10, 2025

What is OSHA's Regional Emphasis Program (REP) for the food manufacturing industry? The OSHA Regional Em...