Safety is a priority in any workplace, especially when working with machinery and equipment. This Lockout Tagout Buying Guide is your comprehensive resource to understand and implement lockout tagout procedures effectively, ensuring the safety of employees and preventing serious accidents. Lockout Tagout (LOTO) is a critical protocol that prevents the unexpected start-up of machinery during service or maintenance, safeguarding workers from potential hazards.

This guide covers various aspects, including the definition and use of lockout and tagout, the importance of hazardous energy control, OSHA requirements, and steps for complete OSHA compliance. Delve into the details of lockout tagout procedure steps, the responsible parties for LOTO, training requirements, and scenarios where lockout must be applied. Learn about different lockout tagout devices, their definitions, and uses, ranging from cable lockouts to valve lockouts, ensuring a thorough understanding of the tools available for implementing this crucial safety protocol.

Whether you are new to lockout tagout or seeking a comprehensive refresher, this guide equips you with the knowledge to prioritize workplace safety effectively.

Read our lockout tagout guide below to learn more and find our selection of tools here!

Lockout Tagout (LOTO) is the protocol that prevents the unexpected start-up of equipment or machinery during service or maintenance procedures.

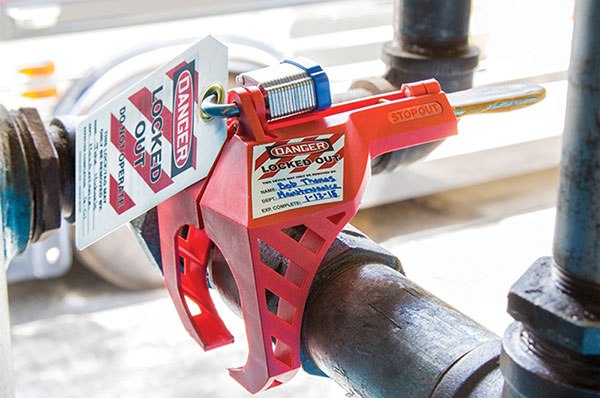

Lockout devices are positive restraints—locking machinery in a safe or “off” position and require a key or combination lock to unlock.

Tagout tags are a warning system—alerting workers and others in the area that they may not use or operate equipment until authorized personnel remove the warning. Tagout tags are easier to remove, providing less protection than lockout devices and should rarely be used by itself.

Lockout devices and tagout systems are used to warn and block employees from potential hazardous energy release from equipment or machinery or unintended start-ups.

Lockout Tagout safety procedures are important to follow as they prevent someone from being able to turn on a device while someone else is working on it—keeping employees safe.

Hazardous energy is any power source that poses a potential danger to workers. Failure to effectively manage stored energy within machines can cause an unexpected release of power.

Lockout is the most reliable method to protect workers from dangerous power sources. The use of a lockout device puts systems in a zero-energy state, eliminating the potential hazards of stored energy.

Procedures for hazardous energy management must detail the following components:

Lockout Tagout is not required by law, although OSHA does have requirements regarding Lockout Tagout safety procedures to keep employees safe.

OSHA requires safety procedures to isolate the machinery from all power sources, preventing the release of potentially hazardous energy.

This section states that employers must establish a plan and employ systems that protect workers when repairing machinery. This standard involves attaching suitable energy-isolating lockout and tagout devices to equipment, preventing stored energy from discharging suddenly.

This regulation states that workers must appropriately tag all deactivated controls during maintenance tasks to warn and inform others of the process.

OSHA does not require specific color codes for LOTO, but below are their recommendations:

A designated person at the facility is responsible for organizing and implementing all energy control procedures. However, all affected employees must be trained on the necessary processes and tasks involved with LOTO safety procedures.

Although training does not actually expire, employees should be retrained whenever there is a change in job assignments, including a change in machine, equipment, or process that may present a new hazard.

Workers must use LOTO procedures under the following circumstances:

Tagout should rarely be used by itself, it does not provide the safety of lockout. Tags are warning systems and do not stop the energization of equipment.

If an employer can prove that a tagout fully protects workers or there is no place to position a lockout device on the machine, you can use a tagout method without a lock.

Before anyone begins work on a locked-out or tagged-out machine, an authorized employee must verify that the equipment's power sources are isolated correctly. They must also confirm there is no remaining stored energy within the system.

The OSHA standard requires the following:

If testing the machinery requires energy, all employees must clear the area during the inspection. If workers must remain near the equipment to complete the test, employers must use alternate safety measures, such as:

Cable Lockouts: A versatile device with a long cable that goes around various isolating components and secures with a padlock.

Chain Lockouts: Chains offer a way to keep people out of large areas that need to be locked out.

Circuit Breaker Lockouts: Electrical isolation locks for circuit breakers.

Energy Source Identification: Identify equipment names and energy sources with safety tags.

Hasps: These devices lock out a single energy control on electrical equipment and machines.

Lock Boxes: Safety devices for ensuring lockout keys are not accessible until workers complete all tasks and return to the lockout box.

Lockout Center Boards: Store LOTO supplies in one place to ensure compliance with safety protocol.

Lockout Documentation: Training forms, booklets, binders and other documentation to explain proper procedures.

Lockout Kits: These collections provide access to necessary safety devices and tools.

Lockout Training: Booklets to supplement your training program and remind workers of LOTO processes.

Padlocks: Trained team members attach these by hand to secure lockout devices.

Plug Lockouts: These tools stop electric currents from energizing machinery by preventing plugs' insertion into a wall outlet.

Security Seals: Tamper-evident seals to add an extra layer of security.

Switch Lockouts: Removable rotary or push-button switch covers to prevent access to controls.

Tagout Tags: Attached to locked out equipment and machines to warn employees of potential danger.

Valve Lockouts: A lockout device to secure the operational portion of a valve.

Worksite Lockouts: These items warn people of dangers and prevent unauthorized access to specific areas.

Shop our Lockout Tagout product selection.

Wendy is Director of Safety and Corporate Compliance, overseeing the implementation of SQF programs and supporting internal teams and distribution centers.

January 12, 2026

Gloves can force a choice between comfort and protection. But compliance, efficiency in usage, and worke...

January 2, 2026

From regulatory updates to evolving needs for operational efficiency, food processors spent 2025 adaptin...

December 10, 2025

What is OSHA's Regional Emphasis Program (REP) for the food manufacturing industry? The OSHA Regional Em...