Delfin pneumatic conveyance for material transport

Pneumatic Conveyance is a system used in industries to move materials using vacuum power, which creates a closed system that prevents product contamination. The system generates a vacuum that moves materials through an airflow and offers benefits such as ease of installation, low maintenance, and improved security of the working environment. Pneumatic conveyors are used in various industries and can improve productivity and environmental health.

What is pneumatic conveyance?

A pneumatic conveyor is a system preferred for moving dust, grain, and solid material from one point to another, exclusively by means of vacuum power. The system is entirely closed, preventing any risk of contamination due to product dispersion during transport.

Compare to traditional conveyor belts >>

|  |  |

| Multi-head weigher load | Dosing machine load | Mixer load & unload |

How does pneumatic conveyance work?

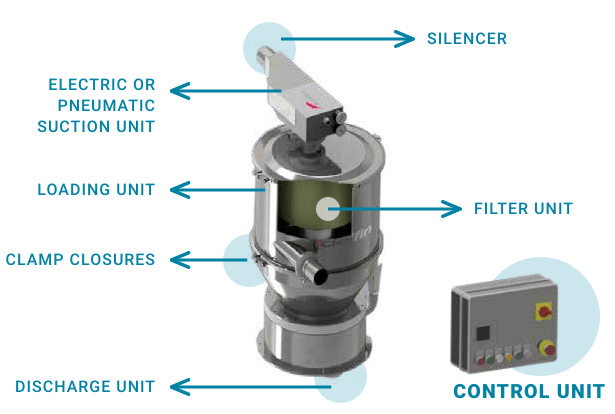

The suction unit generates a vacuum inside the system; the material moves consequently thanks to the airflow. The system allows the automatic transfer of the product by simply connecting it with one or more pieces of processing, production, or packaging equipment. Airflow can transport material in the dense phase (Venturi unit or lobe pump), avoiding the risk of de-mixing or mechanical breakage, or in the diluted phase (side channel blower).

Pneumatic conveyance applications

Pneumatic conveyors can be used in several industrial fields to move dust, grain and solid material. They can improve productivity and efficiency by up to 30%.

- Handling

- Distribution

- Separation

- Blending

- Load/discharge

- Dosage

Advantages of pneumatic conveyance

- Low initial investment

- Easy installation and use

- Low-wear, no maintenance required

- Encumbrance-free departments

- Improves environmental health

- Safe for use in potentially explosive atmospheres

- Improved security of working environment

- Easy to sanitize

- No alternation or contamination of product

Delfin pneumatic conveying solutions

Pneumatic conveyance for cheese curds

What are the types of pneumatic conveyance?

Pneumatic conveying systems come in two primary types: dilute phase and dense phase

Dilute phase systems are designed for high-speed transport of material with low depressions, utilizing a higher percentage of air and a lower concentration of material. While this method allows for faster transportation, it may not be suitable for maintaining material integrity or preventing demixing. On the other hand, dense phase conveying employs a higher concentration of material and lower air percentage, resulting in slower but more compact product movement.

Dilute phase pneumatic conveyors

Dilute phase pneumatic conveying involves transporting products in pipes with a lower concentration of the material and a higher percentage of air compared to dense phase conveying. This method allows for faster transportation with relatively low depressions.

However, since the product tends to float inside the pipes, it may not be suitable for preserving the material's integrity or preventing de-mixing.

Dense phase pneumatic conveyors

Dense phase pneumatic conveying is a method of transporting products through pipelines using a high concentration of product and a lower percentage of air, compared to diluted phase. This results in slower and more compact movement of the product, creating real product cores in high-depression areas.

This configuration is ideal for preserving the product's integrity and preventing de-mixing. If you're looking for a method to transport your product in a slow and compact way without compromising its quality, consider dense-phase pneumatic conveying.