Marking and identification of contents in pipes and piping systems is important for both safety and maintenance. Pipe markers are used to visibly identify contents, flow directions, and hazard classification, thus promoting a safe working environment. Use the below legend and information to help you choose the correct pipe marker for your application.

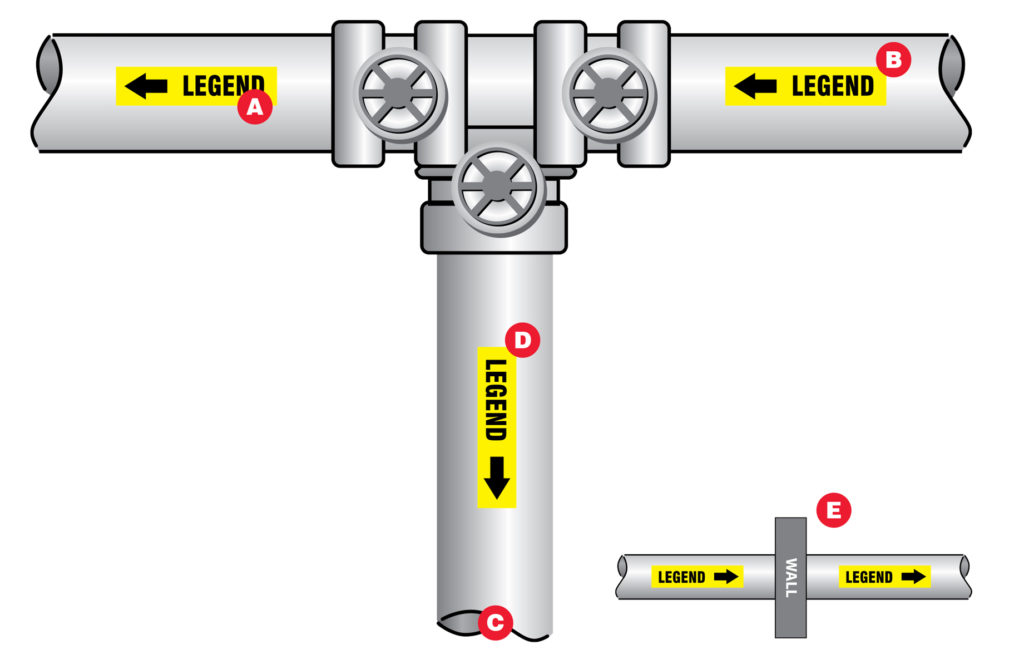

A. Legend

The legend on the marker gives the name of the contents in full or abbreviated form. Arrows should be used to indicate direction of flow.

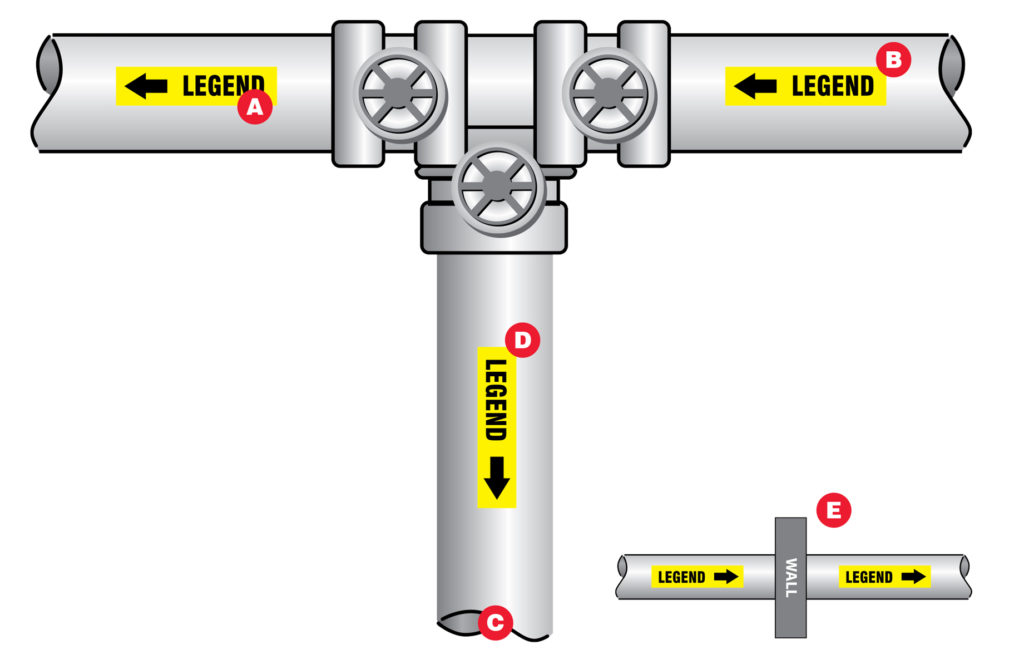

B. Color

Colors can also identify the hazardous character of the contents in the pipes. ASME A13.1-2007 Scheme for the identification of Piping Systems states that a uniform system for the identification of piping contents has been established to warn personnel when the piping contents are inherently hazardous. This standard has been prepared to specify the identification of the contents of piping systems on the basis of legends, it also suggests the use of color as a supplementary means of identifying the type of hazard of the material contained in the system. Below are the colors that ASME recommends:

C. Pipe Outside Diameter

Pipe outside diameter, including insulation, determines the letter height and the length of pipe marker color field.

| Outside Diameter of Pipe | Length of Pipe Marker Color Field | Size of Letters |

| ¾ to 1-¼" | 8" | ½" |

| 1-½ to 2" | 8" | ¾" |

| 2-½ to 6" | 12" | 1-¼" |

| 8 to 10" | 24" | 2-½" |

| Over 10" | 32" | 3-½" |

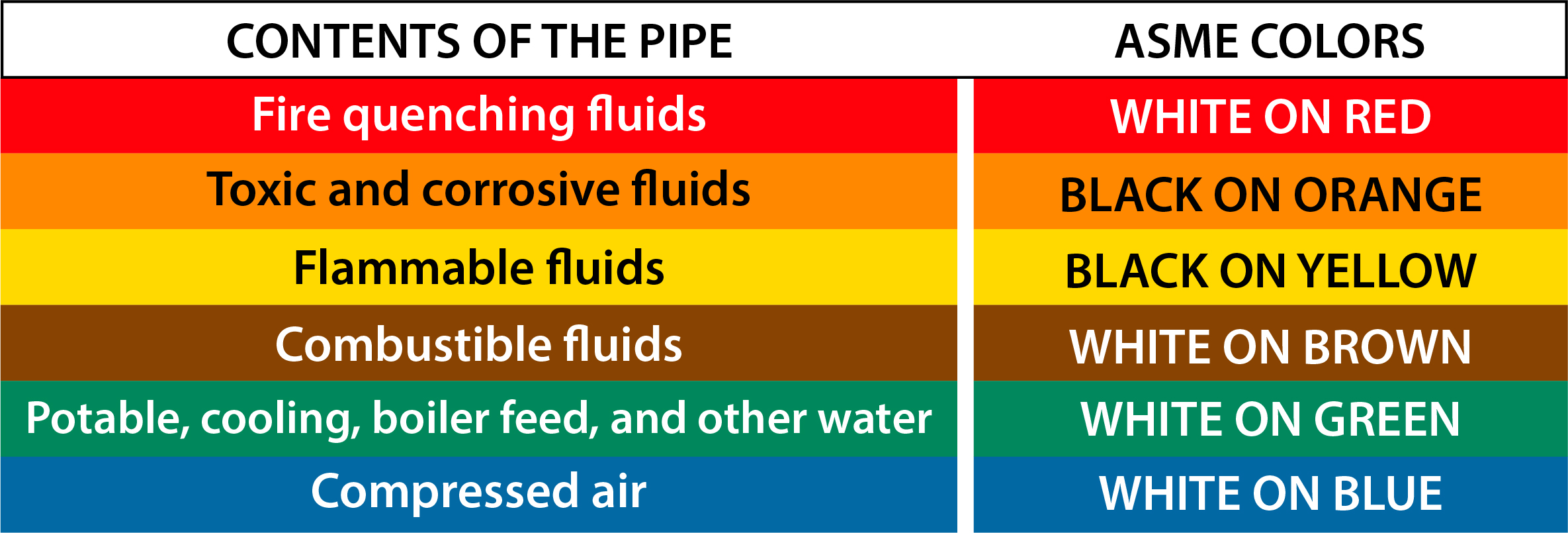

D. Materials

Choose the correct material to fit the application.

E. Visibility & Location

Pipe markers are used to visibly identify contents, flow directions and hazard classification of material moving through pipes. Visibility and location of the pipe markers are very important. Make sure the pipe markers can be read from a distance. Some installation recommendations are:

- Above or below center visual line of pipe.

- Frequent intervals on straight pipe runs and visible from any point along the length.

- Close to valves.

- Near branches and Ts in piping.

- Any change in direction of piping.

- Near points before and after pipe goes through walls, ceilings, or floors; and at 25' to 50' intervals on long straight pipe runs.

| Product | Surface | Material | Temperature Range | Maximum Rec. Size | UV Resistance | Chemical Resistance | Abbrasion Resistanc |

| Self-Stick Vinyl | Gloss | Laminated Vinyl | -20° to 176°F | 4-½" x 32" | Yes | Good | Good |

| Cling-Tite | Gloss | Polyester/Vinyl | -40° to 302°F | 25" x 12" | Yes | Excellent | Excellent |

| Snap Tite™ | Matte | Rigid Vinyl | -4° to 158°F | 25" x 12" | No | Good | Fair |

| Band-Strap Plastic | Gloss | Polycarbonate | -50° to 190°F | 4-½" x 32" | Yes | Excellent | Excellent |

| Big Wrap™ | Matte | Reinforced Vinyl | -4° to 158°F | 168" x 36" | No | Good | Good |

| Reflective Self-Stick | Gloss | Laminated Reflective Vinyl | -30° to 200°F | 4-½" x 32" | Yes | Excellent | Excellent |

| Snap Tite™ Stencil | Matte | Rigid Vinyl | -90° to 168°F | 17" x 39" | Yes | Good | Good |

Pipe Marker Material

Self-Stick Vinyl

- 4 mil flexible vinyl overlaminated with a 2 mil, UV resistant polyester film to withstand harsh environments.

- High-tack, acrylic adhesive back with peel-off liner.

- Adheres to clean, smooth pipe surfaces.

- Service temperature range: -20° to 176°F.

- Directional flow arrow included.

Additional materials are available. Please contact our Facility Identification specialist for more information.

Information provided by AccuformNMC.

Shop our selection of pipe markers.