In February I had the opportunity to attend the “Artisan Dairy Producer Food Safety Initiative Workshop” to learn about the Food Safety Modernization Act (FSMA) along with other leaders in the dairy industry here in Wisconsin. It was put on by the Wisconsin Cheese Makers Association and was offered at no expense thanks to a generous grant from USDA-NIFA. Marianne Smukowski, from the Center for Dairy Research (CDR) and Matt Mathison from the Wisconsin Milk Marketing Board (WMMB) were the trainers for the workshop. The workshop was a brief overview of the expectations that the FDA has put before every business in the food industry, from the large to the small plants. This workshop was geared towards the dairy industry, focusing on the hazards that arise, and how to put a detailed plan together to prevent them. One of the hazards that was of special interest, especially due to the sheer amount of news coverage that it has gotten in the previous months, was the elimination and prevention of Listeria monocytongenes in raw milk, cheeses, and Ready-to-Eat (RTEs) products.

In February I had the opportunity to attend the “Artisan Dairy Producer Food Safety Initiative Workshop” to learn about the Food Safety Modernization Act (FSMA) along with other leaders in the dairy industry here in Wisconsin. It was put on by the Wisconsin Cheese Makers Association and was offered at no expense thanks to a generous grant from USDA-NIFA. Marianne Smukowski, from the Center for Dairy Research (CDR) and Matt Mathison from the Wisconsin Milk Marketing Board (WMMB) were the trainers for the workshop. The workshop was a brief overview of the expectations that the FDA has put before every business in the food industry, from the large to the small plants. This workshop was geared towards the dairy industry, focusing on the hazards that arise, and how to put a detailed plan together to prevent them. One of the hazards that was of special interest, especially due to the sheer amount of news coverage that it has gotten in the previous months, was the elimination and prevention of Listeria monocytongenes in raw milk, cheeses, and Ready-to-Eat (RTEs) products.

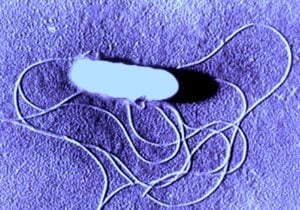

Listeria monocytongenes is a gram-positive microorganism that does not form itself into a spore when dormant, doesn’t need oxygen to reproduce and can grow between -0.4 and 50° C (31.28 and 122° F). L. monocytongenes can be found in numerous places in our environment, including water, soil, dust, plants, animal feed, feces, and sewage. When it comes to the dairy plant, Listeria has been mostly found in moist environments including drains, floors, coolers, conveyors, and case washing areas. Pasteurizing is the most effective way of destroying Listeria, but if post-contamination occurs Listeria growth can swiftly get out of control. Listeria can quickly multiply to dangerous levels, and despite proper refrigeration can continue to multiply.

Listeriosis is the foodborne illness that is caused by Listeria monocytongenes. It is estimated that it affects 1,600 people every year in the U.S and it is known to kill 19.5% of those sickened by it. Much like any foodborne illness it can affect the immuno-compromised, the elderly, and it is also known to impair and sometimes kill fetuses.

So what can be done to prevent the contamination of Listeria? First and foremost a detailed safety plan that segregates raw milk and the tools and equipment used before pasteurization from the pasteurized milk is absolutely necessary. This can be assisted by using a color-coding system to keep brushes, squeegees, pails, etc. from being cross-contaminated with raw milk. Just recently Nelson-Jameson put out a new Color-Coded Catalog highlighting the numerous products that can be put in place to create a zoning system to prevent the cross-contamination that is so dangerous to product. You can check out that catalog here. Another important part of preventing Listeria is developing an environmental cleaning, sanitizing and monitoring program. Nelson-Jameson carries a variety of ATP monitoring systems to help with this. Check out this previously featured, easy-to-understand blog, that breaks down what ATP is and what luminometers can do to assist in ensuring cleaning efficacy. We also carry quick swabs that can specifically be used to test equipment for Listeria.

Unfortunately, recalls due to Listeria keep popping up. Nelson-Jameson is provides the tools and instruments to help prevent recalls. Not only does Nelson-Jameson provide you the luminometers, swabs, brushes, and other equipment needed, but we also do our best to help our customers search out educational opportunities that can be so powerful in helping understand and combat food safety threats.

For instance, our partners at Cherney College have a variety of classes that could be helpful in preventing Listeria along with any other microorganisms from entering product. Some of the classes from Cherney college include: “Environmental Monitoring & Sanitation Essentials,” “Introduction to Food Microbiology-The Basics,” “Advanced Food Microbiology” along with a few others. Check out their website for dates. Mention that you are a Nelson-Jameson customer at checkout and receive 10%. In addition, the CDR has some great short courses, including, “Wisconsin Cleaning and Sanitation Workshop,” “HACCP Workshop,”, and “Milk Pasteurization” that can assist with helping plants become safer. Together, and through educational opportunities like those mentioned here, the food and dairy industries can take on the challenges of the Food Safety Modernization Act, fight food safety threats like Listeria, and ensure a safe food supply for the nation.

February 11, 2026

There is a critical link between worker safety and food safety, and nowhere is this more apparent than w...

February 3, 2026

Ensuring the safety and quality of dairy products requires a robust framework combining rigorous testing...

January 12, 2026

Gloves can force a choice between comfort and protection. But compliance, efficiency in usage, and worke...

Recognize and address possible hygiene and sanitation challenges based on the cleaning and material handling equipment available in your facility.

Through a discovery call, virtual, or on-site assessment, Vikan SQF Practitioner certified specialists will assist in confirming that your system and cleaning tool inventory aligns with your risk management objectives while pinpointing any missing tools and enhancing maintenance and usage practices. Evaluate whether your existing tools are utilized in the most effective manner, or determine if a more suitable tool exists for the task at hand. Ensure that your tools comply with all relevant standards and regulatory requirements. Site evaluations encompass a summary survey, an overview of the location, a color-coded factory layout plan, product suggestions, a recommended order form, and a proposal for a follow-up survey.

Food Safety, Sanitation, Cleaning Tools, Color Coding

This is a comprehensive program for the food processing industry. Nelson-Jameson brings together the most extensive collection of color-coded products for material handling, product handling, janitorial, safety, apparel, QA/QC, and metal-detectable applications. With the right pieces, a color-coding system is a powerful tool in preventing cross-contamination of allergens and food-borne illnesses that can lead to sickness or expensive product recalls.

Food Safety, Sanitation, Cleaning Tools, Color Coding

Food Safety

Get Petrifilm Certified through our complimentary immersive workshop for managers, personnel, and teams. The workshop offers practical knowledge through hands-on training and networking with industry professionals and experts. Attendees gain an in-depth understanding of Petrifilm technology and valuable insights into effective environmental monitoring practices. Participants leave with a certification and a wealth of resources that can significantly contribute to elevating their plant's quality control standards.

Food Safety, Sanitation, Laboratory